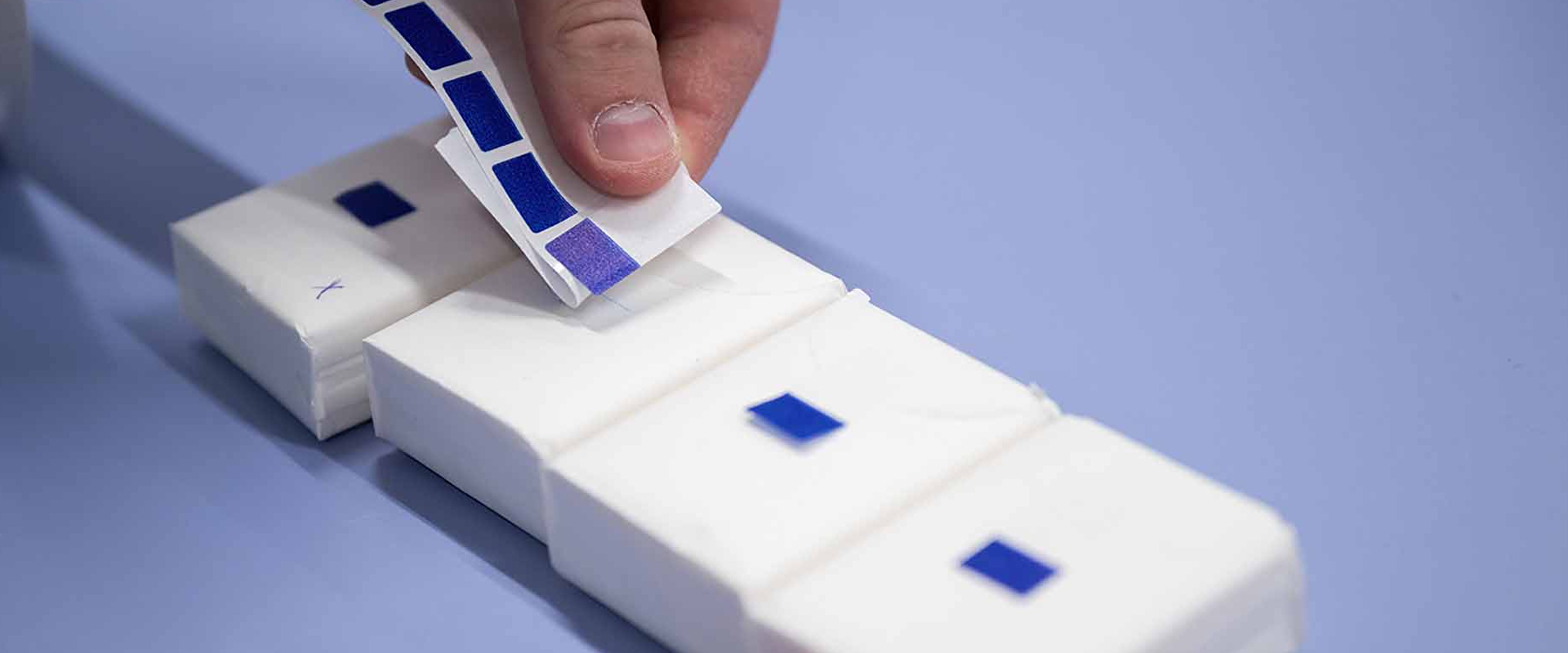

Step 1: Adhesive Selection

The first step in the process is choosing the right adhesive in combination with the substrate the tape needs to adhere to. Factors taken into account include:

- Type of surface: rough or smooth

- Surface energy: low or high

- Desired functionality: permanent adhesion or removable application